ALT-A Auto Labeling Machine

This labeling machine for round bottle is one of updated products of our company. It has a simple and reasonable structure, which is easy to operate. The production capacity shall be adjusted steplessly according to different sizes and characteristics of the bottles and the label papers. It can be applied to the various bottles for food, medicine and cosmetics, etc. Whether it is single or double sided labeling, transparent or nontransparent self-adhesive label for case bottles and flat bottles or other containers will certainly satisfy the customers.

|

Model |

ALT-A |

|

Label Width |

20-130mm |

|

Label Length |

20-200mm |

|

Labeling Speed |

0-100 bottles/h |

|

Bottle Diameter |

20-45mm or 30-70mm |

|

Labeling Accuracy |

±1mm |

|

Work Orientation |

Left → Right (or Right → Left) |

This equipment belongs to the automatic side labeling machine series, which is suitable for side labeling of flat bottles, round bottles and square bottles, such as medicine bottles, syrups, shampoo flat bottles, hand sanitizer round bottles and other products.

This equipment can be used as a stand-alone machine, or it can be used in combination with other equipment to form a production line. Used with a coding machine, it can print information such as electronic supervision code, production date, batch number, printing bar code, two-dimensional code bar code traceability system, etc. on the label.

It can also be matched with product inspection function to realize the visual inspection and rejection function of products, and it can increase the automatic production line and the palletizing robot to box and box the downstream packaging products.

1. The equipment has a wide range of use, and can be adjusted to meet the labeling and self-adhesive products of different specifications and different styles.

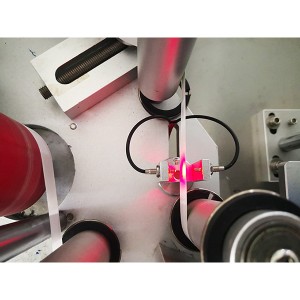

2. The equipment has high labeling accuracy. The equipment uses stepper motors or servo motors to deliver labels, which is accurate and efficient and have their own label deflection correction design to ensure that the labels are not affected by left and right deviations during operation.

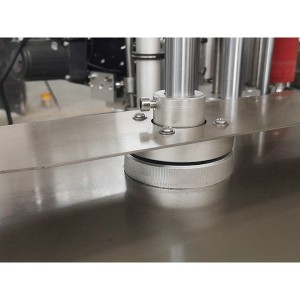

3. The equipment is sturdy and durable, the frame is designed and produced with high-quality materials, and the three-bar adjustment mechanism is adopted to ensure the stable production of the equipment.

4. The performance of the equipment is reliable, imported components are used, and the quality is assured and reliable.

5. Simple adjustment and humanized design make the equipment have a high degree of freedom of adjustment, and the conversion of different products is simple and quick.

6. The equipment is intelligently controlled, using automatic photoelectric tracking, with no bottle subsidy label, automatic label correction function, to prevent leakage or waste.