Our goal is to work closely with our customers by designing and manufacturing pharmaceutical equipment no matter whether it is standard or complicated, and offering the best solution to fulfill all our customers’ needs. This is why we have earned the ongoing trust of our customers worldwide.

■ Cooperation year: 2007

■ Customer's country: Yemen

Background

This customer is a pharmaceutical distributor with no experience in the field of drug manufacturing. They requested to establish a pharmaceutical solids production line. Unfamiliar with equipment operation and lack of skilled operators are two main shortcomings.

Solution

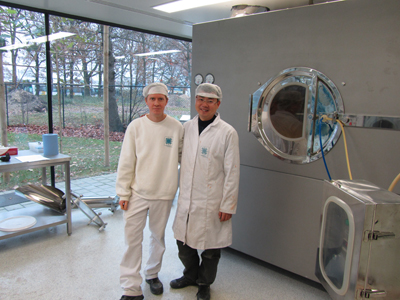

We have recommended a complete solution for the solid dosage manufacturing line, and assisted customer in installation and commissioning of the entire production line. Besides, our engineers have trained customer’s operators at their site by extending the train time form original one and half months to three months.

Result

The customer's pharmaceutical factory has been certified in accordance with GMP standard. The factory has been operating for over a decade since day of production line establishment. At present, this customer has expanded its scale by establishing two pharmaceutical factories. In 2020, they placed a new order from us.

This project contains a production process from raw material processing, granulation, capsule production, tableting to final packaging.

| ■ Production equipment ■ Solid tablet presses ■ Water treatment system ■ Granulator ■ Capsule filling machine |

■ Tablet coating machine ■ Blister packing machine ■ Cartoning machines ■ And more |

Project period: the entire project was completed successfully within about 6 months

■ Cooperation year: 2015

■ Customer's country: Turkey

Background

This customer was requiring the construction of a complete tablet production line at a factory that is located in a remote area where the transportation is inconvenient, and they want to build an energy-efficient air-conditioning system.

Solution

We offered a complete solution through every process of crushing, sieving, mixing, wet granulation, tablet pressing, filling and cartoning. We helped customer to accomplish factory designing, equipment installation & commissioning, and air conditioner mounting.

Result

Coupled with energy-efficient air-conditioning system, our tablet production line benefited customer in saving production cost and assisted them in obtaining GMP certification.

■ Cooperation year: 2010

■ Customer's country: Indonesia

Background

This customer has strict requirements for the quality of solid dosage manufacturing line and requested to get a competitive price. Based on quick updating of their products, supplier’s strength is highly required. In 2015, they have placed an order of orally dissolving film making machine.

Solution

We have provided the customer with 3 solid dosage manufacturing lines, including crusher, mixer, wet granulator, fluid bed granulator, tablet press, tablet coating machine, capsule filling machine, blister packaging machine and cartoning machine. These pharmaceutical equipment are particularly appreciated by the customer.

In addition, we have successfully developed thin oral film making and packaging machines with our constant improvement in response to the customer’s requirement of orally dissolving film making machine.

■ Cooperation year: 2016

■ Customer's country: Algeria

Background

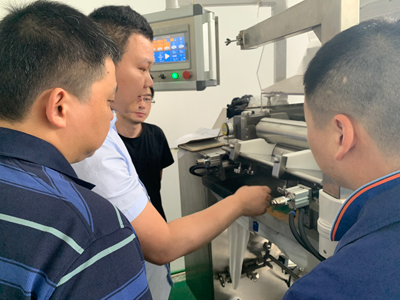

This customer was focusing on after-sales service. They started to cooperate with us by purchasing a cartoning machine. Since the customer is not familiar with the machine operating, we have sent our engineer two times to their plant for commissioning and machine operation training until their operators are able to operate the equipment properly.

Result

Our high quality products and excellent services have earned customer's trust. After that, we have delivered several complete solutions for syrup production line, water treatment equipment and solid dosage production line.

■ Cooperation year: 2018

■ Customer's country: Tanzania

Background

This customer was requiring two solid dosage manufacturing lines and one syrup oral liquid production line (bottle unscrambler, bottle washing machine, filling and closing machine, aluminum foil sealing machine, labeling machine, measuring cup insertion machine, cartoning machine).

Solution

During the communication period of one year, we have sent our engineers to customer's site twice for field inspections, and the customer also came to our plant for three times. In 2019, we have finally reached the intention of cooperation by contracting and supplying all equipment for their plant pipeline construction, boiler water treatment, 2 solid dosage manufacturing lines and 1 syrup oral liquid production line with a complete solution.