Low MOQ for China Rapid Wet Mixer Granulator

Dedicated to strict high-quality regulate and considerate shopper service, our experienced staff members users are constantly available to discuss your necessities and assure full buyer pleasure for Low MOQ for China Rapid Wet Mixer Granulator, Our merchandise delight in excellent popularity among our buyers. We welcome consumers, business enterprise associations and good friends from all components with the globe to make contact with us and seek out cooperation for mutual rewards.

Dedicated to strict high-quality regulate and considerate shopper service, our experienced staff members users are constantly available to discuss your necessities and assure full buyer pleasure for China Wet Granulator, Wet Granulating Machine, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we’ve got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

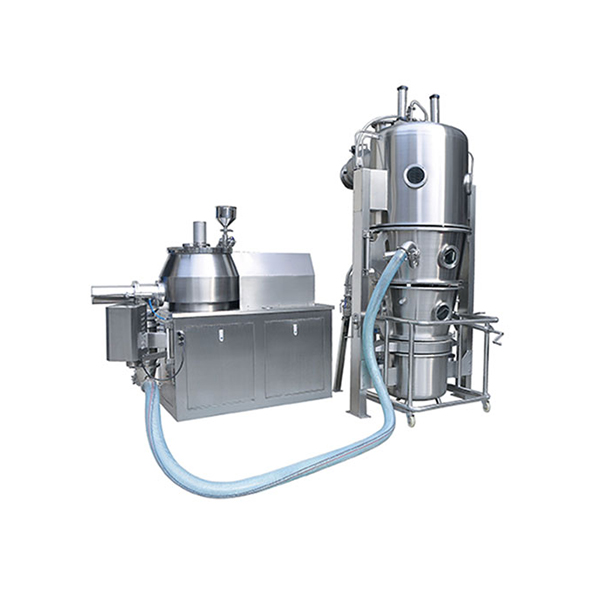

The process consists of two programs including mixing and granulating.

Powder material can be charged into the material pan from the conical hopper and continue to rotate in the container under the action of mixing blade once the hoper is closed. In the meanwhile, all materials grow up the shape of liquid bridge under continuous effects of conical wall. Under the action of extrusion, friction as well as crumb by blade and conical tank wall, all material is gradually turn for loosen. At last while opening the hopper outlet, waterish particles are pushed off under the centrifugal effects blade.

● With consistent programmed technology (Man-machine interface if option selected), ensuring the equipment of stability in quality, as well as easy manual operation for convenience of technological parameter and flow progress.

● Adopt frequency speed adjustment for stirring blade and cutter, easy to control the size of particle.

● With the rotating shaft hermetically filled with air, it can prevent all dust from compact.

● With a structure of conical hopper tank, all material can be in uniform rotation. The tank is laid with an interlayer on the bottom, in which water cooling circulation system featuring higher thermostatic performance than air cooling system is furnished, which leads to improve the quality of particles.

● With automatic lifting of the pan cover, the tank outlet matching with drying device, self-equipped arm-ladder, it is easy to operate.

● Lifting system with paddle is more beneficial to clean paddles and pot body.

● Mouth of material outlet has changed Into arc-shaped, avoiding up dead spaces.

| Model | HLSG-10 | HLSG-30 | HLSG-50 | HLSG-100 | HLSG-200 | HLSG-300 | HLSG-400 | HLSG-600 | HLSG-800 |

| Hopper capacity | 10L | 30 | 50L | 100L | 200L | 300L | 400L | 600L | 800L |

| Working capacity | 2-8L | 6-24 | 10-40 | 20-80 | 40-160 | 60-240 | 100L-300L | 150L-440L | 200L-600L |

| Feed qty | 1-4 Kg/batch | 3-12 Kg/batch | 8-20Kg/batch | 15-40 Kg/batch | 30-80Kg/batch | 30-120Kg/batch | 50-150Kg/batch | 75-220Kg/batch | 100-300Kg/batch |

| Operation time | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 2 minutes granulating about 7-14 minutes each batch | Mixing about 4 minutes granulating about 10-15 minutes each batch | Mixing about 8 minutes granulating about 15-20 minutes each batch | Mixing about 8 minutes granulating about 15-20 minutes each batch |

| Finished product granularity | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.14-Φ1.5mm (12 mesh-100 mesh) | About Φ0.10-Φ2.5mm |

| Mixing motor | 2.2KW | 3KW | 5.5KW | 7.5KW | 15KW | 18.5KW | 22KW | 30KW | 37KW |

| Mixing blade rotating speed | 50-500 rpm | 25-500 rpm | 25-500 rpm | 30-250 rpm | 30-260 rpm | 30-220 rpm | 20-200 rpm | 20-200 rpm | 20-200 rpm |

| Granulating motor | 0.75KW | 1.1KW | 1.5KW | 3KW | 4KW | 5.5KW | 7.5KW | 11KW | 11KW |

| Granulating blade rotating speed | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm | 50-3000 rpm |

| Compressed air | 0.15m³ 0.7mpa | 0.15m³ 0.7mpa | 0.3m³ 0.7mpa | 0.3m³ 0.7mpa | 0.3m³ 0.7mpa | 0.5m³ 0.7mpa | 0.5m³ 0.7mpa | 0.5m³ 0.7mpa | 0.6m³ 0.7mpa |

| Cooling water connector | Φ8mm | Φ8mm | Φ8mm | Φ8mm | Φ10mm | Φ10mm | Φ10mm | Φ10mm | Φ12mm |

| Compressed air port | Φ8mm | Φ8mm | Φ8mm | Φ8mm | Φ10mm | Φ10mm | Φ10mm | Φ10mm | Φ12mm |

| Mahcine size | 1280×530×1320 mm | 1500×550×1350 mm | 1750×600×1620 mm | 1760×600×1660 mm | 2180×810×1950 mm |

2420×1060×2150 mm |

2420×1060×2150 mm |

2980×1200×2500 mm |

3180×1500×2800 mm |

| weight | 350kg | 450kg | 600kg | 800kg | 1300kg | 1500kg | 1800kg | 2200kg | 2700kg |

Dedicated to strict high-quality regulate and considerate shopper service, our experienced staff members users are constantly available to discuss your necessities and assure full buyer pleasure for Low MOQ for China Rapid Wet Mixer Granulator, Our merchandise delight in excellent popularity among our buyers. We welcome consumers, business enterprise associations and good friends from all components with the globe to make contact with us and seek out cooperation for mutual rewards.

Low MOQ for China Wet Granulator, Wet Granulating Machine, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we’ve got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.