18 Years Factory Sublingual Strip Machine - Aseptic Filling and Closing Machine (for Vial), KHG-60 Series – Aligned

18 Years Factory Sublingual Strip Machine - Aseptic Filling and Closing Machine (for Vial), KHG-60 Series – Aligned Detail:

| Model | KHG-60 |

| Filling capacity | 10-100ml |

| Output | 0-60 vial/min |

| Filling accuracy | ±0.15-0.5 |

| Air pressure | 0.4-0.6 |

| Air consumption | 0.1-0.5 |

This machine is a filling, stoppering and capping machine for vials. This machine adopts a closed cam indexing station with high precision, reliable operation and long service life. The indexer has a simple structure and does not require maintenance for long-term use.

This machine is suitable for filling, plugging and screwing (rolling) various small-dose liquids, such as essential oils. It is widely used in the food, pharmaceutical, chemical industry and scientific research fields. This machine can not only be produced as a single machine, but also can be combined with a bottle washer, dryer and other equipment to form a linked production line. Meet GMP requirements.

1. Man-machine interface setting, intuitive and convenient operation, PLC control.

2. Frequency conversion control, arbitrary adjustment of production speed, automatic counting.

3. Automatic stop function, no filling without bottle.

4. Disc positioning filling, stable and reliable.

5. High-precision cam indexer control.

6. It is made of SUS304 and 316L stainless steel, which meets GMP requirements.

For the filling and sealing of liquid preparations in the pharmaceutical industry, it is mainly composed of a spindle, auger feeding into the bottle, a needle mechanism, a filling mechanism, a rotary valve, auger discharging a bottle, and a capping station.

1. Convey medicine bottles in a straight line at a high speed, and the design speed can reach 600 bottles/min.

2. The filling needle adopts the reciprocating tracking method to fill and rotate the stopper and press the stopper under the condition of the movement of the medicine bottle.

3. It can be applied to a variety of specifications, and can automatically adjust the filling volume, the height of the filling needle and the production speed of the entire system according to the specifications of various bottles.

4. At the same time realize the functions of no bottle no filling and no bottle no stopper.

5. The production data and product data can be retained for a long time, and the production formula data can be modified.

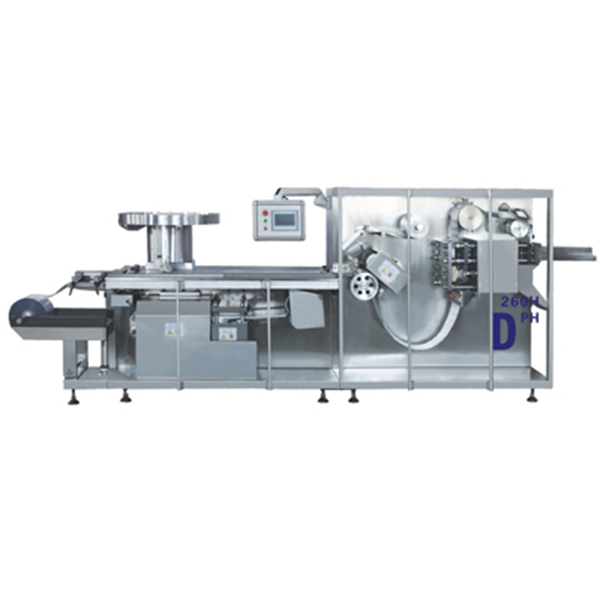

Product detail pictures:

Related Product Guide:

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for 18 Years Factory Sublingual Strip Machine - Aseptic Filling and Closing Machine (for Vial), KHG-60 Series – Aligned , The product will supply to all over the world, such as: British, Mexico, Surabaya, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!