Products

-

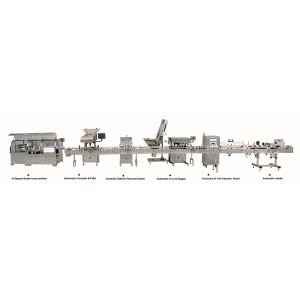

Automatic Tablet&Capsule Counting & Packaging Line

Automatic Tablet/capsule Counting & Capping Line is widely used in pharmaceutical, food, chemical and other industries, and is suitable for product packaging of different shapes and sizes, such as capsules, tablets, candies, powders, etc. The multi-lanes feeder automatically counts and filling in plastic bottles, glass bottles, jars and other containers. With its stability and compliance with GMP requirements, our equipment guarantees reliable and consistent performance.

-

TF-20 Automatic Effervescent Tablet Tube Filling Machine

Effervescent tablet filling machine offers high output, stable performance, and fully automatic operation. It’s equipped with automatic alarm and stop functions when there are no tablets, bottles, or caps. This makes it the most ideal equipment for packaging effervescent tablets in pharmaceutical, healthcare, food, and similar packaging factories.

-

ZP Series Automatic Rotary Tablet Press Machine

ZP Series Rotary Tablet Press Machine is a mechanical device used in industries such as pharmaceuticals, food, chemicals, and industrial production to manufacture tablets. It utilizes a rotating turret with punches and dies to compress powder or granular materials into tablet form.

This equipment incorporates features for efficient material handling, such as powder feeding systems, hopper mixers, and dust removal systems, ensuring the stability of the Tablet Press Machine while minimizing material waste and pollution risks.

ZP Series Rotary Tablet Press Machine boasts high automation, enabling continuous tablet production, resulting in higher productivity and reduced labor costs.

-

4M Automatic Oral thin film making machine

The Oral Strip Machine is specialized in making liquid materials into thin film. It can be used to make quick-dissolvable oral films, transfilms, and mouth freshener strips, having wide application range in pharmaceutical field, food industry and etc.

-

10M OTF &Transdermal Patch Making Machine

OZM340-10M equipment can produce Oral thin film and Transdermal Patch. Its output is three times that of medium-scale equipment, and it is the equipment with the largest output at present.

It is a special equipment for laying liquid materials evenly on the base film to make thinner film materials, and adding a laminated film on it. Suitable for medicine, cosmetics, and health care products industries.

The equipment adopts frequency conversion speed regulation and automatic control technology integrated with machine, electricity and gas, and is designed in strict accordance with the “GMP” standard and “UL” safety standard of the pharmaceutical industry. The equipment has the functions of film making, hot air drying, laminating, etc. The data index is controlled by the PLC control panel.It can also be selected to add functions such as deviation correction、slitting.

The company provides professional technical support and after-sales service, and assigns technical personnel to customer enterprises for machine debugging, technical guidance and personnel training.

-

BG-E Series Coating Machine

The machine is widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc. In such fields as of pharmaceutical, food and biological products etc. And it has such characteristics as good appearance in design, high dfficiency, low energy consumption and small floor area, etc.

-

ZPW Series Rotary Tablet Press Machine

ZPW series tablet press machine is a machine with automatic rotation, frequency control and continuous tablet pressing. It is mainly used in the manufacture of tablets in the pharmaceutical industry, and it is also used in chemical, food, electronics and other industrial sectors to compress granular raw materials into tablets.

-

DPP-260 Automatic Flat Blister packing Machine

DPP-260 Automatic Blister packing Machine is our advanced equipment designed under updated improvement. Adopts of the integral technology applying frequency inverter for speed control and mechanism, electricity, light, and air to machine. Its design is in strict compliance with GMP standards and takes lead in the blister packer’s field. Featuring advanced functions, simple operation, high output, and the machine is ideal packing equipment for large and medium-size pharmaceutical enterprises, health food, and foodstuff plant.

-

SL Series Electronic Tablet-Capsule Counter

SL Series Electronic Tablet/Capsule Counter is specialized for counting the products of medicine, health care, food, agricultural chemicals, chemical engineering, and so on. For example tablets, coated tablets, soft/hard capsules. The machine can be used alone as well as with other machines produced by our company to form a complete producing line.

-

CFK Series High Speed Automatic Capsule Filling Machine

CFK series products are the latest automatic capsule filling machines developed by our company. Through multiple bold innovations and repeated trials, our company has obtained nearly 20 patent certificates, making the CFK series capsule filling machine more aesthetically pleasing, stable in operation, low in noise, easy to operate, and easy to clean.CFK series automatic capsule filling machine is suitable for powder and granule filling of 00#-5# capsules. It can be equipped with auxiliary equipment such as automatic capsule feeder, vacuum loading machine, metal detector, polishing machine and lifting machine according to different usage scenarios.

-

DPH Series Roller Type High Speed Blister Packing Machine

DPH Roller Type High-Speed Blister Packing Machine with advanced performance, simple operation, high output is the latest improved equipment in our company. It is the best ideal packing equipment for large and medium-sized pharmaceutical plants, health care factory and the food industry. It is much faster and more productive than flat type blister packing machine. It adopts no waste side punching, can save more than $50,000/year materials.

-

CGN-208D Semi-Automatic Capsule Filling Machine

It’s suitable for filling powder and granular material in pharmacy and health food industry.