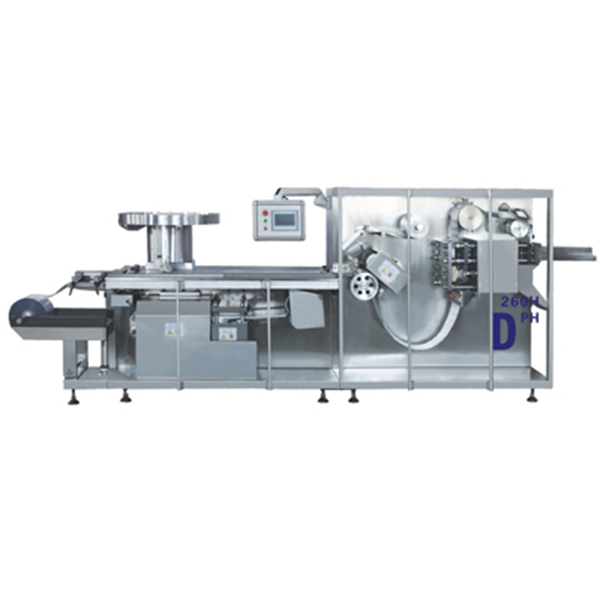

2021 High quality Automatic Liquid Pouch Packing Machine - ALY Series Auto Eyedrop Filling Monobloc – Aligned

2021 High quality Automatic Liquid Pouch Packing Machine - ALY Series Auto Eyedrop Filling Monobloc – Aligned Detail:

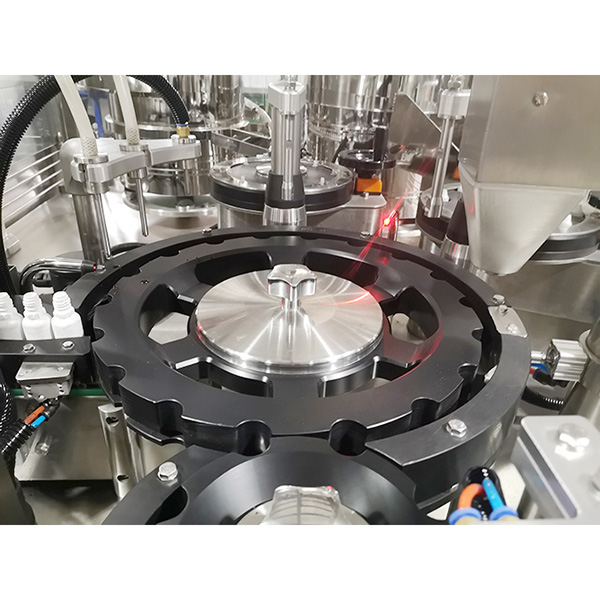

The machine is auto-liquid filling equipment combined with filling, plug inserting and cap screwing in one unit. –the bottle feeding into bottle unscrambler, and rotate and output into filling machine;

–Sensor will inspect the feeding bottle, and if the number of bottles is less than fixed amount, the filling machine will stop filling;

–Within rotating disc, sensor will inspect if there is a bottle, no bottle, no filling;

–Finished filling, automatic plug inserting will be achieved;

–Plugs should be inspected, otherwise, no plugging, no cap placing;

–The last step will be screwing the cap;

– Finished filling and capping, the bottles will go through image sensor to detect if there is any defect, and the defected bottles will be rejected to rejection bin and the qualified bottles will be sent out to downstream machines through output conveyor belt. (Note: defected bottles including 3 kinds: no insert and no cap; with insert, no cap; crooked capping;)

|

Model |

ALE-100 |

ALE-200 |

|

Filling volume |

1-10ml |

|

|

Capacity |

Max. 100bottle/min |

Max. 200bottle/min |

|

Filling accuracy |

±0. 1% |

|

|

Air pressure |

0.4-0.6 |

|

|

Air consumption |

0.1-0.5 |

|

|

Power |

5KW |

7KW |

It is widely applied to filling, adding of corks and caps, caps tightening for flowing liquid in such industries as pharmacy, biology, food, daily necessities and cosmetics etc.

1.With novel design philosophy, its manufacture, safety performance are carried out according to European standards and conform to GMP requirement as well.

2.It is furnished with highly efficient filters of international famous brands to effectively ensure sterility and cleanness of class-A area. Air blower, filter and other equipment adopt sinking-type design structure to realize easy, reliable overhaul and replacement.

3.Materials adding is completely isolated from operating area. Those areas requiring artificial interference are furnished with glove boxes to prevent class-A area from being destroyed.

4.Through machine-gas -electricity combination, full-automatic operation can be realized including bottles entering, filling, adding of inner corks and outer caps, caps tightening and sorting of defective.

5.Filling adopts high-precision ceramic plunger pumps or peristaltic pump structure. High-precision filling volume, non-leakage and high efficiency are ensured through servo drive quantification.

6.Bottle mouths are added with inner corks. Outer caps adopt structure of mechanical hands to ensure accurate positioning fast and efficient adding of caps.

7.The inside of caps tightening device adopts German torsion clutch or servo power twister to effectively ensure bottle caps are undamaged under the premise that they are tightened.

8.Filling is not conducted when bottles are not in place. Adding of outer caps is not conducted when bottles are not in place. Adding of outer caps is not conducted when inner corks are not in place. Defective products are automatically sorted out via sensor testing and conveyed into defective area for inspection, thus isolating defective products.

9.Rotary operating discs can be exchanged according to bottles of different sizes and shapes to meet users’ demands.

10.Main actuating mechanisms of this machine all adopt servo motors in effective combination with different forms of cylinders and unique mechanical structure. It is a new generation of special filling equipment initially developed in China, with high degree of automation, high finished product ratio, wide adaptability, good stability and high output etc.

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for 2021 High quality Automatic Liquid Pouch Packing Machine - ALY Series Auto Eyedrop Filling Monobloc – Aligned , The product will supply to all over the world, such as: European, Monaco, Peru, We have more than 10 years experience of production and export business. We always develop and design kinds of novel products to meet the market demand and help the guests continuously by updating our products. We are specialized manufacturer and exporter in China. Wherever you are, please join us, and together we will shape a bright future in your business field!

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.