2021 High quality Tube Filling Sealing Machine - ALRJ Series Vacuum Mixing Emulsifier – Aligned

2021 High quality Tube Filling Sealing Machine - ALRJ Series Vacuum Mixing Emulsifier – Aligned Detail:

Including main emulsifying pot, water pot ,oil pot and work frame.

Usually the oil pot is used for dissolving some solid that the product can just only be dissolved into oil, then the dissolved solvent will be sucked into the emulsify pot by soft pipes.

The function of water pot is the same to the oil pot.

Emulsify pot is used for emulsifying the products that suck from the oil pot and water pot.

| Model | Effective Capacity | Emulsify | Agitator | Dimensions | Total Power(kw) | |||||

| kw | r/min | kw | r/min | Length | width | weight | Max H | |||

| ALRJ-20 | 20 | 2.2 | 0-3500 | 0.37 | 0-40 | 1800 | 1600 | 1850 | 2700 | 5 |

| ALRJ-50 | 50 | 3 | 0-3500 | 0.75 | 0-40 | 2700 | 2000 | 2015 | 2700 | 7 |

| ALRJ-100 | 100 | 3 | 0-3500 | 1.5 | 0-40 | 2120 | 2120 | 2200 | 3000 | 10 |

| ALRJ-150 | 150 | 4 | 0-3500 | 1.5 | 0-40 | 3110 | 2120 | 2200 | 3100 | 11 |

| ALRJ-200 | 200 | 5.5 | 0-3500 | 1.5 | 0-40 | 3150 | 2200 | 2200 | 3100 | 12 |

| ALRJ-350 | 350 | 7.5 | 0-3500 | 2.2 | 0-40 | 3650 | 2650 | 2550 | 3600 | 17 |

| ALRJ-500 | 500 | 7.5 | 0-3500 | 2.2 | 0-40 | 3970 | 2800 | 2700 | 3950 | 19 |

| ALRJ-750 | 750 | 11 | 0-3500 | 4 | 0-40 | 3780 | 3200 | 3050 | 4380 | 24 |

| ALRJ-1000 | 1000 | 15 | 0-3500 | 4 | 0-40 | 3900 | 3400 | 3150 | 4550 | 29 |

| ALRJ-1500 | 1500 | 18.5 | 0-3500 | 7.5 | 0-40 | 4000 | 4100 | 3750 | 5650 | 42 |

| ALRJ-2000 | 2000 | 22 | 0-3500 | 7.5 | 0-40 | 4850 | 4300 | 3600 | No lift | 46 |

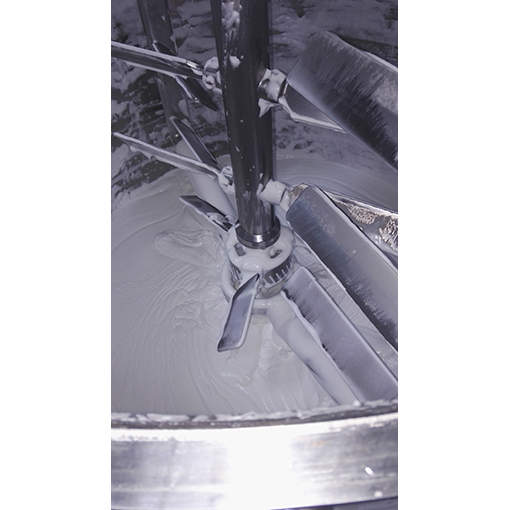

The vacuum emulsifier shears, disperses and impacts the materials through the high-speed rotation of the homogenizing head connected with the engine. In this way, the material will become more delicate and promote the integration of oil and water. The principle is to use a high-shear emulsifier to quickly and evenly distribute one phase or multiple phases to another continuous phase in a vacuum state. It uses the strong kinetic energy brought by the machine to make the material narrow in the stator and rotor. In the gap, it is subjected to hundreds of thousands of hydraulic shears per minute. The combined effects of centrifugal squeezing, impact, tearing, etc. instantly disperse and emulsify uniformly. After high-frequency cyclic reciprocation, high-quality products without bubbles, delicate and stable, are finally obtained.

The vacuum emulsifier includes a pot body, a pot cover, a foot, a stirring paddle, a stirring motor, a stirring support, a feeding device, a discharge pipe, and a vacuum device. The product feeding device is located at the bottom of the pot, and the product vacuum device is connected with The aforementioned feeding device cooperates to form an automatic suction operation. Compared with the prior art, the vacuum emulsifier can directly add the light suspended materials into the pot and mix them evenly, and can realize automatic control of the feeding.

1. The new mixing concept of vacuum emulsifier-can ensure the high quality of the product and shorten the production time.

2. Customized design of functional modules, the vacuum emulsifier has more functions and flexibility.

3. The homogenizing head can choose the appropriate dispersing head according to the different characteristics of the material. After emulsification, the particle size is small and fine, the product is uniform, and it can remain stable even for a long time.

4. There is a spiral stirrer in the pre-mixing tank, and the vacuum emulsifying machine can ensure the stable and full mixing of the materials in the tank.

5. Mix well in the vertical and horizontal directions

6. The scraper is very flexible. The food vacuum emulsifier can rotate in the reverse direction, has no dead ends, can be heated and cooled, and the time is greatly shortened.

7. The entire mixed production process adopts PLC modern electronic touch screen operation, which can be adjusted according to requirements

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for 2021 High quality Tube Filling Sealing Machine - ALRJ Series Vacuum Mixing Emulsifier – Aligned , The product will supply to all over the world, such as: Namibia, Florida, belarus, After 13 years of researching and developing products, our brand can represent wide range of products with outstanding quality in world market. We have completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.