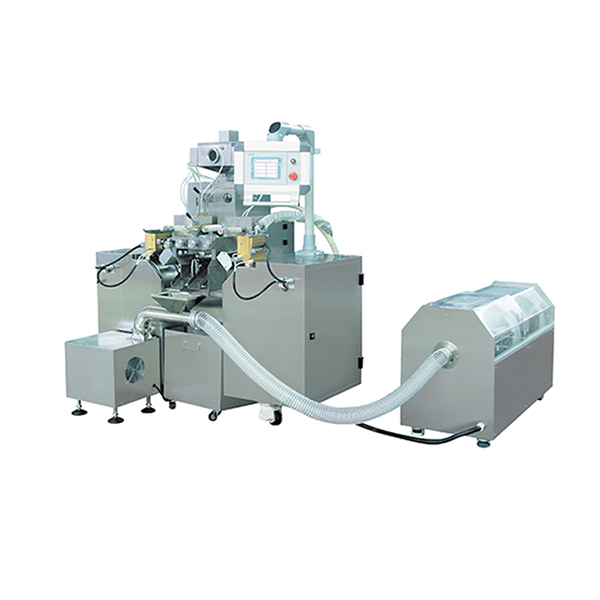

Europe style for Gelatin Capsule - NJP-260 Automatic Liquid Capsule Filling Machine – Aligned

Europe style for Gelatin Capsule - NJP-260 Automatic Liquid Capsule Filling Machine – Aligned Detail:

1. Touch-Screen, PLC program control panel with LCD.

2. Capsule vacuum positioned mechanism to make the capsule qualified over 99%.

3. Easy speed selection and closed capsule length adjustment.

4. Electrical Appliance control system approved to CE, and international standard.

5. Quick and accurate change part set-up easy to remove rotary table and ring carrier assembly.

6. Fully enclosed rotary table and dosage station for integration of the whole capsule filling plants.

7. Large cam mechanism keeps the rotating table of mould together with the whole equipment running in balance, and completely guarantees the machine operating with highest precision and accuracy.

|

Model |

NJP-260 |

|

Weight |

900kg |

|

Dimension |

1020×860×1970mm |

|

Motor Power |

5.75kw |

|

Voltage |

Three-phase four wire AC 380V;50Hz |

|

Max Capacity |

1200 pcs/min |

|

Method of heat & dry |

Heating by external stainless-steel heater, hot air circulation in centrifugal fan |

|

Capsule Size |

00#~5#,Safety type capsule A~E |

|

Rate |

≥99.5% |

|

Noise |

≤75dBA |

|

Accuracy |

Above 300m ≤±3%(After granulation, the pellets within 40~80 mesh) |

|

Compressed Air |

0.06m3/min 0.3Mpa |

|

Water Requirement |

Water ring vacuum pump with the use of water tanks, but also external water sources |

|

Vacuum Degree |

-0.02~-0.06 MPa |

|

Water Flow |

250L/h |

|

Inlet Diameter |

20mm |

|

Inside Diameter Of Drain Pipe |

27mm |

|

Working Environment Temperature |

21℃±3℃ |

|

Plant Height Requirements |

Manual feeding≥2.6m,Vacuum feeding≥2.8m |

|

Relative Humidity of Working Environment |

40~55% |

|

Air Exhaust Volume |

300m3/h |

|

Control System |

frequency stepless speed regulation,PLC control |

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for Europe style for Gelatin Capsule - NJP-260 Automatic Liquid Capsule Filling Machine – Aligned , The product will supply to all over the world, such as: Sudan, Ireland, Israel, With the growing of the company, now our products sold and served at more than 15 countries around the world,such as Europe,North America,Middle-east,South America,Southern Asia and so on. As we bear in our mind that innovation is essential to our growth, new product development is constantly.Besides, Our flexible and efficient operation strategies,High quality products and competitive prices are exactly what our customers are looking for. Also a considerable service brings us good credit reputation.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.