factory Outlets for Emulsifying Mixer - Capsule Polisher, JFP-110A – Aligned

factory Outlets for Emulsifying Mixer - Capsule Polisher, JFP-110A – Aligned Detail:

| Model | JFP-110A |

| Capacity | 150,000 pcs/hour |

| Power supply | 220V 50 /60HZ, 1P, 0.18kw |

| Gross weight | 60kg |

| Net weight | 40kg |

| Negative pressure | 2.7m3 /min -0.014Mpa |

| Compressed Air | 0.25m3 /min 0.3Mpa |

| Overall dimension | 800*500*1000mm |

| Package dimension | 870*600*720 |

The capsule polishing machine is a special polishing equipment for capsules, which can remove dust on the surface of the capsule and improve the surface finish. It is suitable for the production of various capsules.

It has the characteristics of novel mechanism, simple operation, easy cleaning, high polishing efficiency, and good cleanliness. All parts in contact with medicines are made of stainless steel, and the sanitary conditions of the equipment conform to GMP standards.

The capsule polishing machine can polish capsules and tablets while removing empty shells and broken capsules. This machine is equipped with an all-stainless steel vacuum cleaner, no other vacuum equipment is needed. Adopting negative pressure rejecting device, no pollution to the environment.

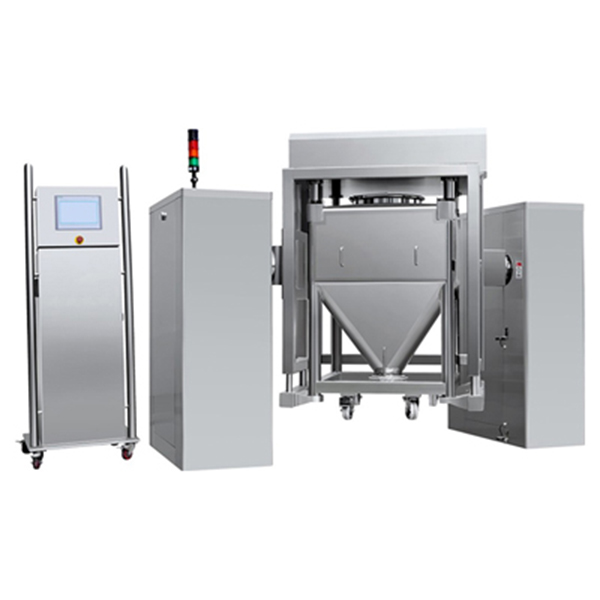

The polishing machine is mainly composed of a hopper, a polishing cylinder, a sealing cylinder, a brush, a coupling, a split bearing seat, a motor, a power distribution box, a waste removal head, a discharge hopper, and a frame.

The working principle of this machine is to drive the capsule to move in a circular spiral along the wall of the polishing tube through the rotating movement of the brush, so that the capsule moves along the spiral spring, and the surface of the capsule shell is polished under the constant friction with the brush and the wall of the polishing tube. , The polished capsule enters the waste hopper from the discharge port. In the de-waste device, due to the effect of negative pressure, the light-weight unqualified capsules rise under the action of the airflow and enter the vacuum cleaner through the suction tube. The heavy-weight qualified capsules continue to fall and are discharged through the movable discharge hopper to effectively achieve polishing. To eliminate the purpose. The powder and small fragments that are brushed off during the polishing process enter the sealed cylinder through the small holes on the wall of the polishing cylinder, and are sucked into the vacuum cleaner for recovery.

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for factory Outlets for Emulsifying Mixer - Capsule Polisher, JFP-110A – Aligned , The product will supply to all over the world, such as: Oslo, Lesotho, Salt Lake City, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.