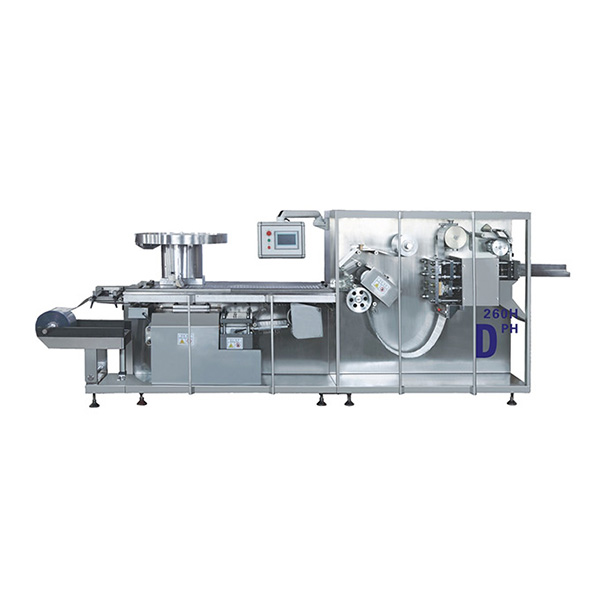

Factory supplied Horizontal Cartoner Machines - Labeling Machine (for Round Bottle), TAPM-A Series – Aligned

Factory supplied Horizontal Cartoner Machines - Labeling Machine (for Round Bottle), TAPM-A Series – Aligned Detail:

| Model | TAMP-A |

| Label width | 20-130mm |

| Label length | 20-200mm |

| Labeling speed | 0-100 bottles/h |

| Bottle diameter | 20-45mm or 30-70mm |

| Labeling accuracy | ±1mm |

| Operation direction | Left → Right (or Right → Left) |

1. It is suitable for round bottle labeling in the pharmaceutical, food, daily chemical and other industries, and can be used for full-circle labeling and half-circle labeling.

2. Optional automatic turntable bottle unscrambler, which can be directly connected to the front-end production line, and automatically feed bottles into the labeling machine to increase efficiency.

3. Optional configuration ribbon coding and labeling machine, which can print production date and batch number online, reduce bottle packaging procedures and improve production efficiency.

1. Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

2. Applicable products: products that require labels or films to be attached to the circumferential surface

3. Application industry: widely used in food, medicine, cosmetics, daily chemicals, electronics, hardware, plastics and other industries

4. Application examples: PET round bottle labeling, plastic bottle labeling, food cans, etc.

After the bottle-separating mechanism separates the products, the sensor detects the passing of the product and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the product to be labeled. The labeling belt drives the product to rotate, the label is rolled, and the attaching action of a label is completed.

1. Place the product (connect to the assembly line)

2. Product delivery (automatically realized)

3. Product correction (automatically realized)

4. Product inspection (automatically realized)

5. Labeling (automatically realized)

6. Override (automatically realized)

7. Collect labeled products (connect to the subsequent packaging process)

Product detail pictures:

Related Product Guide:

owing to excellent assistance, a variety of high quality products and solutions, aggressive costs and efficient delivery, we take pleasure in an excellent popularity amongst our customers. We are an energetic business with wide market for Factory supplied Horizontal Cartoner Machines - Labeling Machine (for Round Bottle), TAPM-A Series – Aligned , The product will supply to all over the world, such as: Burundi, Nigeria, Plymouth, All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.