Good Quality Standard Operating Procedure For Liquid Filling Machine - ALF-3 Rotary-Type Liquid Filling, Plugging And Capping Monobloc – Aligned

Good Quality Standard Operating Procedure For Liquid Filling Machine - ALF-3 Rotary-Type Liquid Filling, Plugging And Capping Monobloc – Aligned Detail:

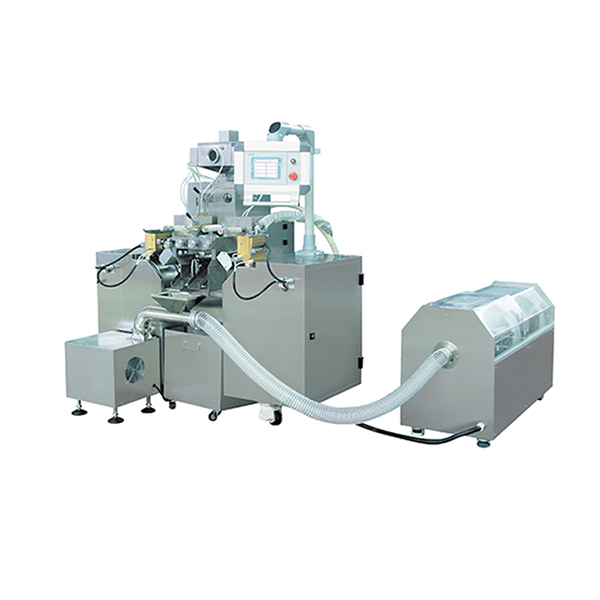

This machine is a filling, stoppering and capping machine for vials. This machine adopts a closed cam indexing station with high precision, reliable operation and long service life. The indexer has a simple structure and does not require maintenance for long-term use.

This machine is suitable for filling, plugging and screwing (rolling) various small-dose liquids, such as essential oils. It is widely used in the food, pharmaceutical, chemical industry and scientific research fields. This machine can not only be produced as a single machine, but also can be combined with a bottle washer, dryer and other equipment to form a linked production line. Meet GMP requirements.

|

Model |

ALF-60 |

|

Filling range |

10-100ml |

|

Capacity |

0-60bottle/min |

|

Filling accuracy |

±0.15-0.5 |

|

Air pressure |

0.4-0.6 |

|

Air consumption |

0.1-0.5 |

This machine is a filling, stoppering and capping machine for vials. This machine adopts a closed cam indexing station with high precision, reliable operation and long service life. The indexer has a simple structure and does not require maintenance for long-term use.

This machine is suitable for filling, plugging and screwing (rolling) various small-dose liquids, such as essential oils. It is widely used in the food, pharmaceutical, chemical industry and scientific research fields. This machine can not only be produced as a single machine, but also can be combined with a bottle washer, dryer and other equipment to form a linked production line. Meet GMP requirements.

1. Man-machine interface setting, intuitive and convenient operation, PLC control.

2. Frequency conversion control, arbitrary adjustment of production speed, automatic counting.

3. Automatic stop function, no filling without bottle.

4. Disc positioning filling, stable and reliable.

5. High-precision cam indexer control.

6. It is made of SUS304 and 316L stainless steel, which meets GMP requirements.

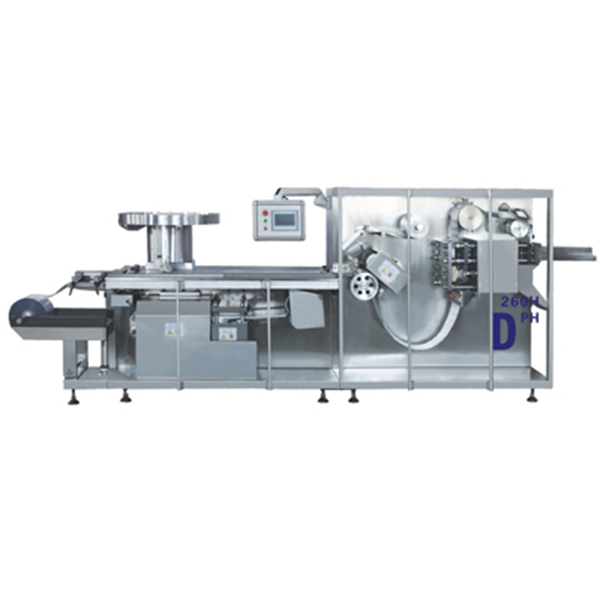

For the filling and sealing of liquid preparations in the pharmaceutical industry, it is mainly composed of a spindle, auger feeding into the bottle, a needle mechanism, a filling mechanism, a rotary valve, auger discharging a bottle, and a capping station.

1. Convey medicine bottles in a straight line at a high speed, and the design speed can reach 600 bottles/min.

2. The filling needle adopts the reciprocating tracking method to fill and rotate the stopper and press the stopper under the condition of the movement of the medicine bottle.

3. It can be applied to a variety of specifications, and can automatically adjust the filling volume, the height of the filling needle and the production speed of the entire system according to the specifications of various bottles.

4. At the same time realize the functions of no bottle no filling and no bottle no stopper.

5. The production data and product data can be retained for a long time, and the production formula data can be modified.

Product detail pictures:

Related Product Guide:

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for Good Quality Standard Operating Procedure For Liquid Filling Machine - ALF-3 Rotary-Type Liquid Filling, Plugging And Capping Monobloc – Aligned , The product will supply to all over the world, such as: Pretoria, Guatemala, Moscow, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.