Good Quality Standard Operating Procedure For Liquid Filling Machine - Automatic Ampoule Forming Filling Sealing Machine – Aligned

Good Quality Standard Operating Procedure For Liquid Filling Machine - Automatic Ampoule Forming Filling Sealing Machine – Aligned Detail:

This machine is suitable for the filling of unit doses of medicines, beverages, dairy products, health products, foods, cosmetics, perfumes, agricultural medicines, fruit pulps, etc.

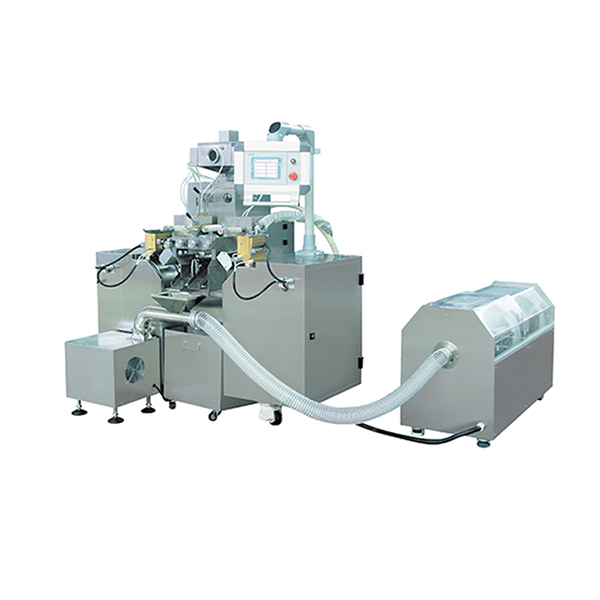

DGS-118 Ampoule Forming Filling & Sealing Machine is applicable for liquid, sticky, semi-sticky and so on. This machine can be used for pharmaceuticals, food, health care products, cosmetic. It also can be used in industry and agriculture in similarity products. This machine can finish forming, filling, sealing once time.

1. Controlled by PLC, the frequency conversion in finely variable speeds.

2. All 6 processes from spreading roll, AMP bottle forming, filling, sealing the end, printing serial numbers, cutting the end, cutting apart, controlled by programming.

3. The computer human interface has a simple and clear operation.

4. The filling head does not drop, leak, rise in bubbles and spill over.

5. All are made of high-quality stainless steel, accord with the standard GMP.

6. Mostly pneumatic components and wirings adopt inward fittings.

7. Automatic and mechanical filling, precise calculation and limited deflection.

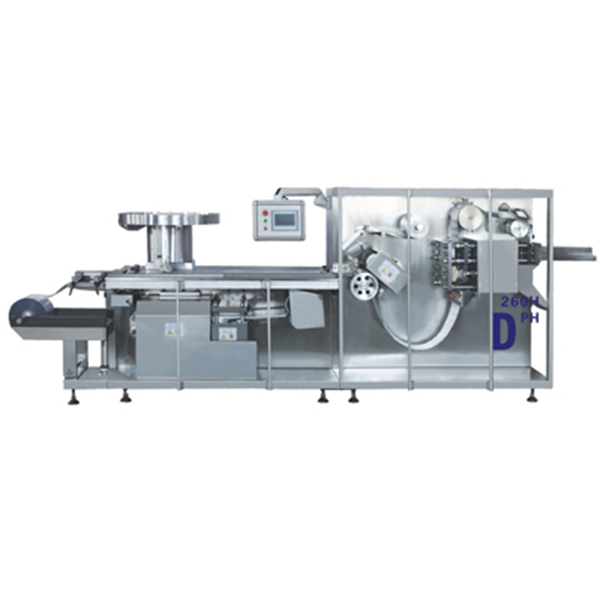

| Model | DGS-118P5 |

| Max forming depth | 16mm |

| Cutting frequency | 0-25 times/min |

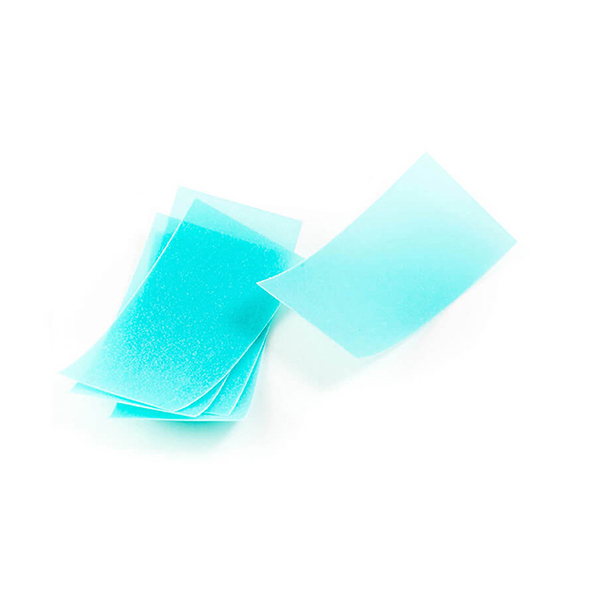

| Packing material | PET/PE, PVC/PE |

| Packing roll | Two roll |

| Filling volume | 1-50ml |

| Filling head | 5 heads |

| Power | 7kw |

| Voltage | 220v-380v/50Hz |

| Size (L×W×H) | 2300×850×1500(mm) |

| Weight | 900Kg |

Product detail pictures:

Related Product Guide:

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for Good Quality Standard Operating Procedure For Liquid Filling Machine - Automatic Ampoule Forming Filling Sealing Machine – Aligned , The product will supply to all over the world, such as: Rotterdam, Bahrain, Curacao, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.