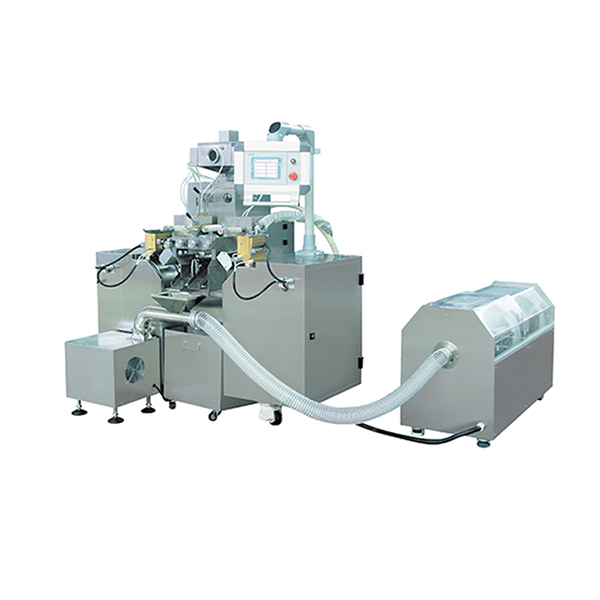

OEM/ODM Manufacturer Solvent Casting Method Film - OZM Film Making Machine – Aligned

OEM/ODM Manufacturer Solvent Casting Method Film - OZM Film Making Machine – Aligned Detail:

| Max. film width | 360mm |

| Roll width | 400mm |

| Production speed | 0.02-1.5m/min (depends on actual status and material) |

| Unwinding diameter | ≤φ350mm |

| Winding diameter | ≤φ350mm |

| Heating and drying method | External stainless steel electric heating tube for heating, centrifugal fan for hot air circulation |

| Temperature control | 30-100℃±0.5℃ |

| Reeling edge | ±3.0mm |

| Total power | 16KW |

| Dimension | 3070×1560×1900mm |

The ODF Machine is specialized in making liquid materials into thin film. It can be used to make quick-dissolvable oral films, trans films, and mouth freshener strips, having wide application range in pharmaceutical field, food industry and etc.

High dosing accuracy, quick dissolving, fast release, no swallowing difficulty, high acceptance by elderly and children, small size convenient to carry.

The working principle of the machine is evenly coated a layer of liquid material on the surface of the reel base roll. The solvent (moisture) is rapidly evaporated and dried through drying channel. And winding up after cooling (or composite with another material). Then, get the final products of the film (composite film).

These equipment adopts frequency conversion speed control and automatic control technology of machine, electric, light and gas, and innovates the design according to the “GMP” standard and the “UL” Safety Standard of the pharmaceutical industry. The Film Making Machine has the functions of film making, air drying and other features. All the data parameters are regulated by the PLC control panel. The model is for the new thin film drugs for continuous improvement, innovation and research and development, its comprehensive performance to the leading domestic level, the technology to fill the gaps, and imported equipment more practical and economical.

Centralized control, console 1 group (setting the man-machine interface, all electrical operation and setting of the whole machine on the touch screen)

1.Unwinding unit

Two units (single station type): Unwinding tension control: semi-auto control (Suzhou Lan ling: 2.5kgf magnetic powder brake, tension controller)

2. Coating unit

One unit (comma scraper coating)

3.Drying oven

One set (drying oven 2m, two thermal areas)

4.Winding unit

One unit (single station centre winding)

Product detail pictures:

Related Product Guide:

Sticking towards the principle of "Super High-quality, Satisfactory service" ,We've been striving to become a superb business partner of you for OEM/ODM Manufacturer Solvent Casting Method Film - OZM Film Making Machine – Aligned , The product will supply to all over the world, such as: Jeddah, Albania, Madras, All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.