2021 wholesale price Soft Gel Encapsulation Machine - High Speed Tablet Press, GZPK-26 Series – Aligned

2021 wholesale price Soft Gel Encapsulation Machine - High Speed Tablet Press, GZPK-26 Series – Aligned Detail:

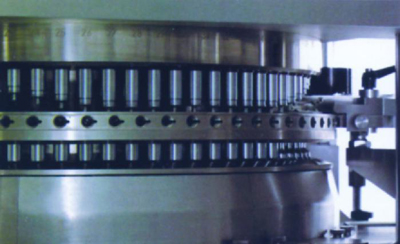

Tablet Compression System

The compression system implements a process consisting of two steps, i.e. pre-compression and main compression. The design of compact structure provides long compression time, stable operation and no deformation under heavy load, significantly ensuring tablet weight accuracy and tablet hardness during large tablet compressing process while guaranteeing the smooth running and low noise level of the machine.

Feeding System

The configuration of double-paddle feeder plays an important role in precise controlling of every tablet weight, it ensures optimal filling of powder to the die bore, eliminating the problems such as insufficient filling of free flowing products, excessive dust and cross contamination that are commonly occurs in ordinary tablet compression machine. This feeding system is featured by high precision and easy to disassemble.

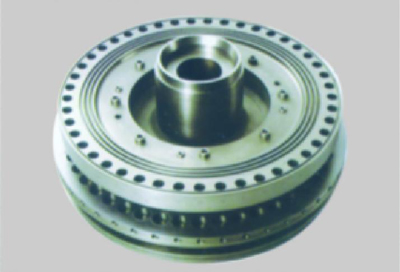

Punch Turret

High precision tablet press turret is made of corrosion resistant materials, providing an excellent protection against rust and corrosion.

Automatic Lubrication System

Three sets of automatic centralized lubrication system are equipped with central lubricating pump and distribution valves to ensure complete lubrication of punches, guiding and compression rollers while protect the tablets from being contaminated by splashing oil.

Human-Machine Interface (HMI)

Human-machine interface (HMI) adopts Siemens 10 inch color touch screen to display filling depth, operating pressure, tablet thickness and other production parameters, allowing operator to easily control the machine.

Imported high precision Tedea-Huntleigh force sensors and amplifiers are used in pressure sensing and transmission system to execute real-time force monitoring and analysis, enabling the powder filling depth to be automatically adjusted and achieving automatic control of tableting process. In addition, the many variables such as tooling damage and powder feeding status are also monitored in real-time, thus maximizing protection, increasing qualification rate, as well as greatly reducing production cost.

| Model | GZPK-26 | |

| No. of stations | 26 | |

| Output (tablets/h) | Max. | 160000 |

| Min. | 30000 | |

| Rotation speed (rpm) | Max. | 102 |

| Min. | 11 | |

| Max. tablet diameter | Ф25 | |

| Main compression force (KN) | 100 | |

| Pre-compression force (KN) | 20 | |

| Max. filling depth (mm) | 20 | |

| Diameter of die (mm) | 38.1 | |

| Length of punch (mm) | 133.6 | |

| Main motor power (kw) | 11 | |

| Dimension (mm) | 800(+440)*890(+440)* 1945 | |

| Net weight (kg) | 1400 | |

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for 2021 wholesale price Soft Gel Encapsulation Machine - High Speed Tablet Press, GZPK-26 Series – Aligned , The product will supply to all over the world, such as: Hyderabad, Juventus, Romania, We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.