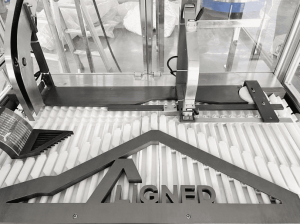

TF-20 Automatic Effervescent Tablet Tube Filling Machine

Automatic Effervescent Tablet Tube Filling Machine is comprised of five essential components: cap feeder, tablet feeder, bottle feeder, bottling mechanism, and capping mechanism. This versatile device is designed for seamless operation in pharmaceutical, healthcare, and food packaging industries.

Effervescent tablet flling machine efficiently fills effervescent tablets into tubes, ensuring precise dosage and stable quality. Its automated features guarantee smooth and reliable performance, while the cap feeder, tablet feeder, and bottle feeder streamline the filling process.

1.Cap feeder: Adopt vibrating plate is used to automatic unscrambling the cap and adjust the direction to automatic feed it into the capping station.

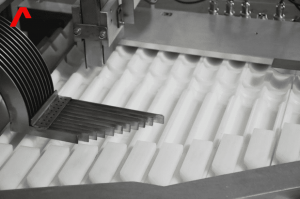

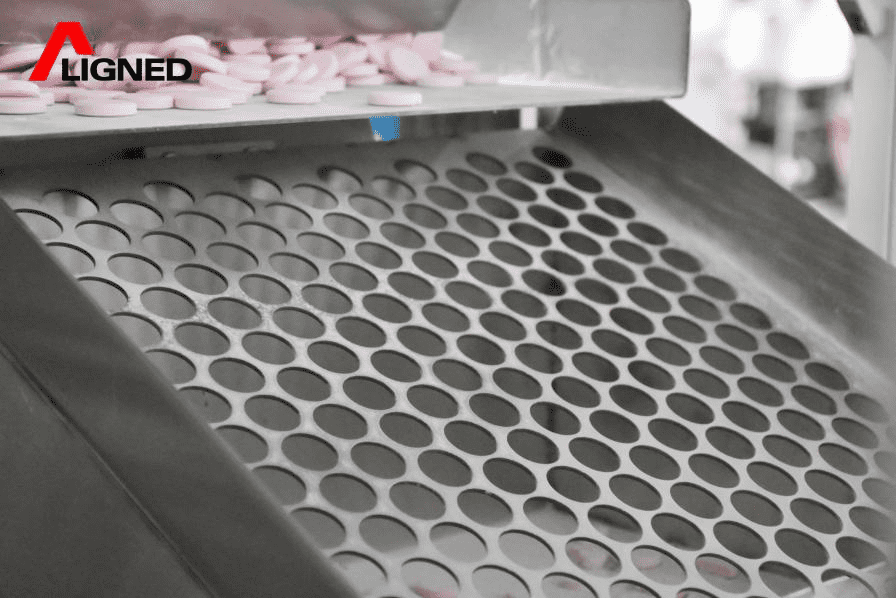

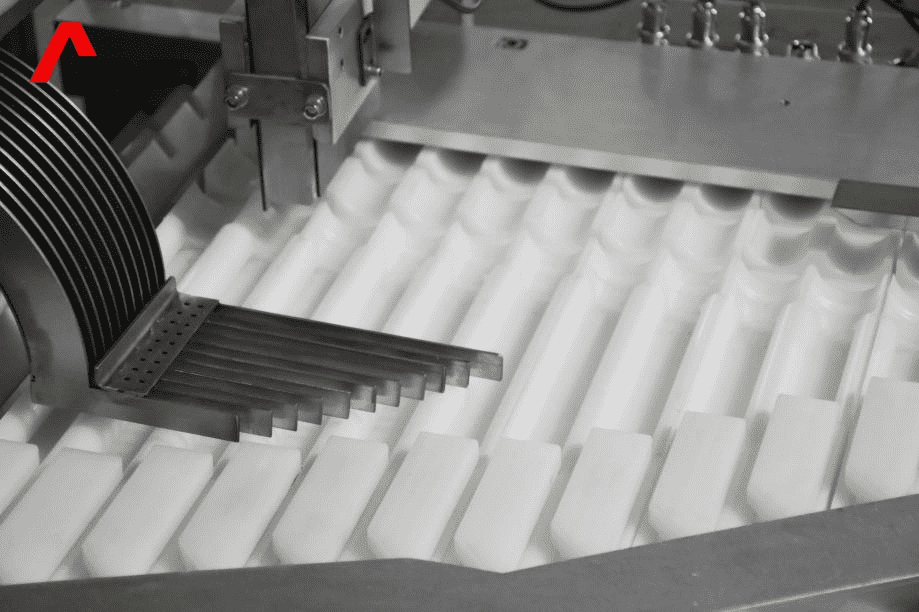

2.Tablet feeder: Adopt vibrating plate to automatic unscrambling the tablets and feed them into the bottling mechanism

3.Bottle feeder: Automatic unscrambling the bottles and send them to the bottling mechanism.

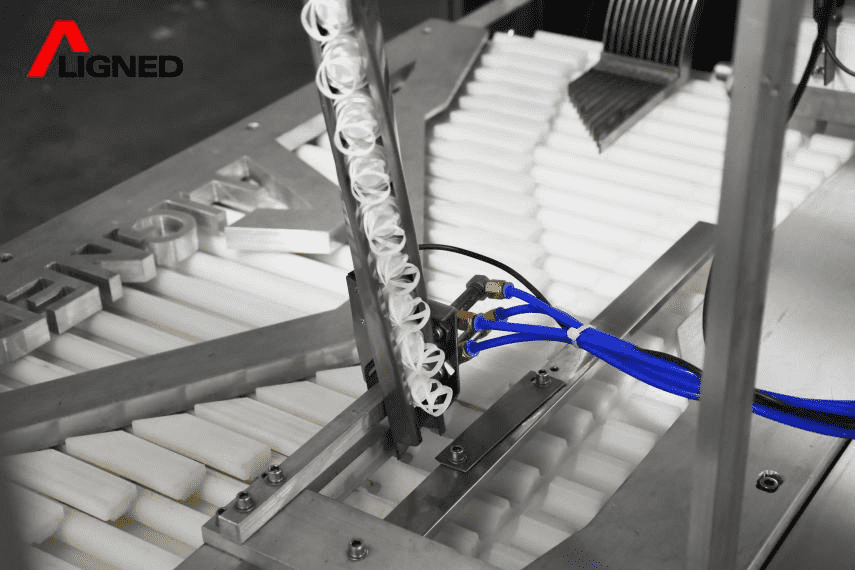

4.Bottling mechanism: Automatic count and arrange the tablets into each track and send them into the bottle

5.Capping mechanism: When a bottle and tablet are detected, the cap is automatic pressed into the bottle.

1. Double detection photoelectricity is adopted to ensure that the tube is not missing pieces.

2. The new design structure greatly reduce the footprint of the equipment.

3. The vibrating turntable feeding method,the speed is more than 1 times faster than the traditional feeding method, and the feeding is smooth, avoiding material blocking the track and reducing material loss.

4. According to different pipe sizes, the pull-out mold can complete mold replacement within 2 minutes, improving production efficiency.

5. Double key start system: one key to start the material in place, one key to start automatic operation.

6. It can be equipped with humidity detection and alarm device.

7. One set of system control can be connected with the labeling machine.

8.The output is stable up to 120 tubes/minute, compared with traditional equipment, the output is increased by 70%.

9.The whole set of equipment can be packaged and transported in separate parts, and the bolts are fixed when combined, and the operation is convenient

|

Max. Output |

120tube/min |

|

Max. Tablet Feeding Speed |

98000pc/h |

|

Tablet Diameter |

16-33mm |

|

Tablet Diameter (minimum-maximum), in Millimeters |

16-33 |

|

Tablet Thickness |

3-12mm |

|

Tablet Hardness |

≥40N |

|

Bottling Quantity |

5-20pc |

|

Tube Length |

60-200mm |

|

Tube Diameter |

18-35mm |

|

Power Supply |

380V 50HZ 3P |

|

Power |

4.5KW |

|

Overall Size |

2500mm*1600mm*1700mm |

|

Weight |

About 480KG |