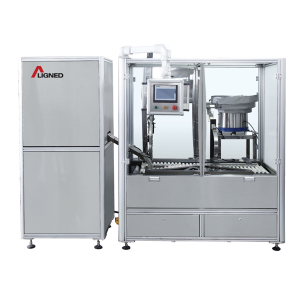

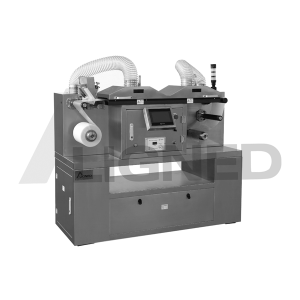

Automatic Slitting and Drying Machine (for Oral Films)

| Production Speed | Standard 0.02m-10m/min | |

| Slitting Film Width | 110-190 mm (Maximum 380mm) | |

| Film Web Width | ≤380 mm | |

| Motor Power | 0.8KW/220V | |

| Power Supply | Single phase 220V 50/60HZ 2KW | |

| Air Filter Efficiency | 99.95% | |

| Air Pump Flow Volume | ≥0.40m3/min | |

| Packaging Material | Slitting Composite Film Thickness (general) | 0.12mm |

| Machine Dimension (L×W×H) | 1930×1400×1950mm | |

| Packaging Dimension (L×W×H) | 2200×1600×2250mm | |

| Machine Weight | 1200Kg | |

ODF, the full name is oral disintegrating membrane. This kind of film is small in quality, easy to carry, and can be quickly disintegrated without being matched with liquid, and can be absorbed efficiently. This is a brand-new dosage form, which is often used in the fields of pharmacy, food, daily chemicals, pet products, etc., and is highly praised by customers.

In the ODF film production process, after the film is completed, it is affected by the production environment or other uncontrollable factors. We need to adjust and cut the film that has been produced, usually in terms of cutting size, adjusting humidity, lubricity and other conditions, so that the film can reach the stage of packaging, and make adjustments for the next step of packaging. This equipment is an indispensable process in the film production process, ensuring the maximum use efficiency of the film.

After years of R&D and production, our equipment has continuously improved problems in experiments, solved equipment problems, improved equipment design problems, and provided strong technical guarantees for better service to customers.

Our equipment can be used to produce different types of film products.

Usually, customers purchase equipment to produce drugs that require rapid absorption to treat various diseases. Such drugs require rapid absorption to achieve rapid problem solving and reduce patient symptoms.

At the same time, our customers are used to produce oral freshener film products. After the membrane is mixed with saliva, the fresh substances in the membrane can be quickly absorbed by the human body to achieve the purpose of refreshing the mouth.

Now that there are more and more ODF products on the market, the demand for products is increasing day by day, and the profit margin of the market is constantly increasing. Excellent equipment can ensure efficient production. While the Aligned team provides you with high-quality equipment, it also provides you with efficient after-sales service, so you no longer have to worry about the future.

Believe in Aligned, believe in the power of faith!